SLS

Selective Laser Sintering

Create your models, props and displays with complex, durable and functional designs without the need for production support structures.

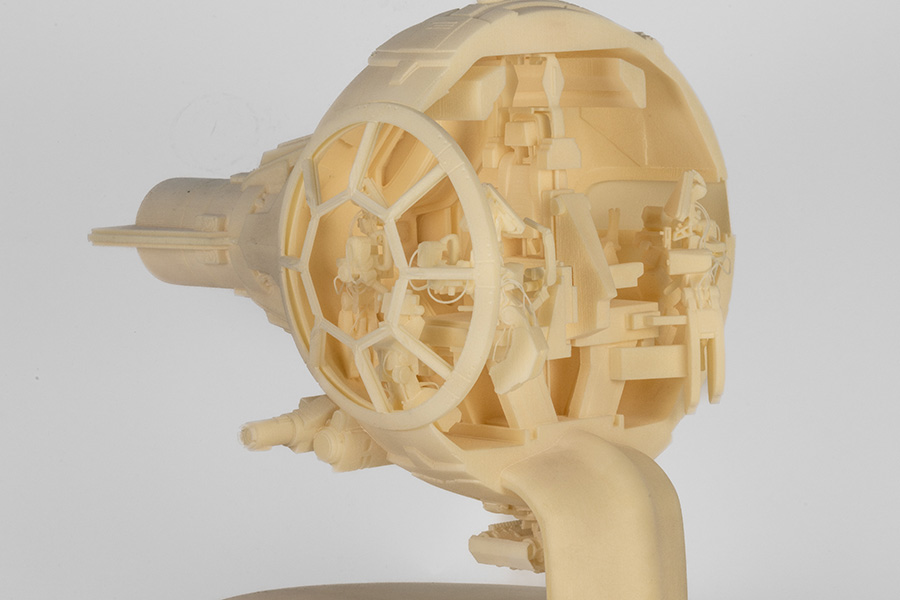

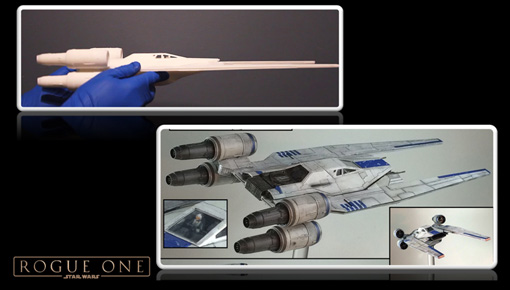

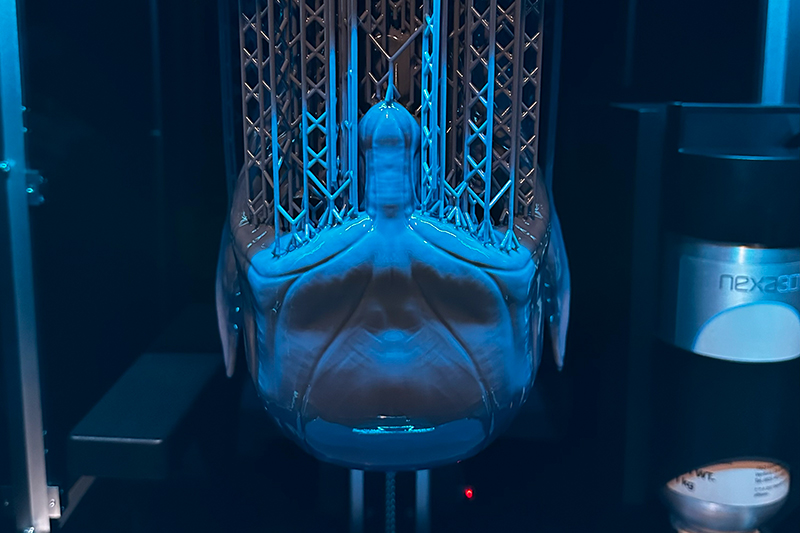

SLA

Stereolithography

Produce highly detailed and accurate models, prototypes, and production parts with exceptional surface finish and mechanical properties.

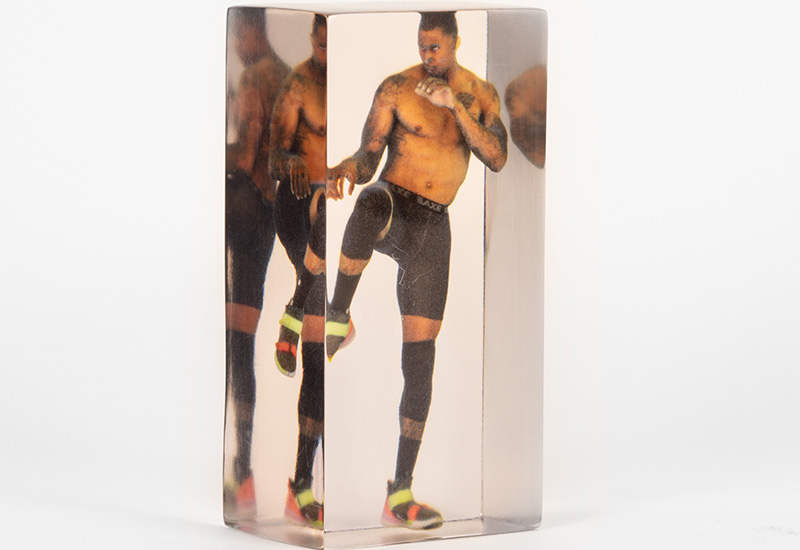

Color

Color 3D Printing

We’re able to bring your creative visions to life with greater flexibility, speed, and cost-effectiveness compared to traditional manufacturing methods.

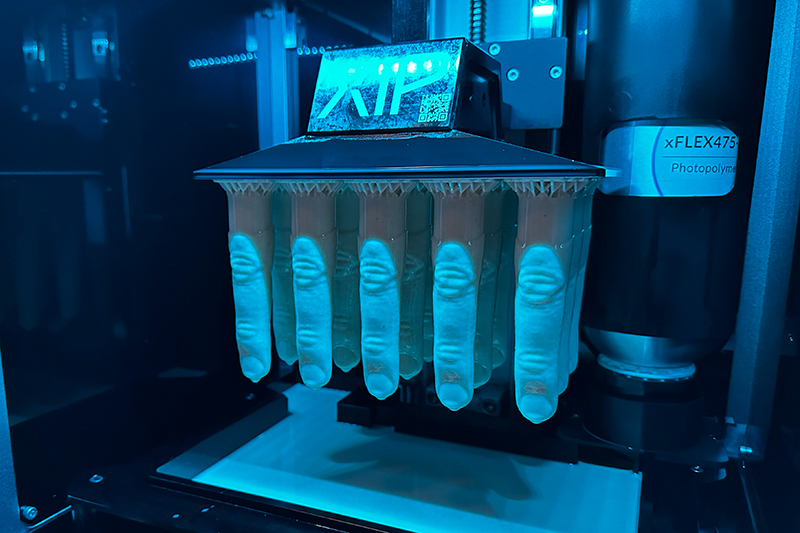

DLP

Digital Light Processing

SLS

Selective Laser Sintering

SLA

Stereolithography

Gentle Giant Studios is renowned for its cutting-edge SLA 3D printing capabilities, setting a benchmark in the realm of high-resolution printing. Utilizing Stereolithography (SLA), we achieve unparalleled precision. We are the preferred choice for intricate prototypes and collectibles alike. The process involves using a UV laser to cure liquid resin layer by layer, resulting in smooth, flawless surfaces that capture even the finest nuances of design. Gentle Giant’s SLA 3D printing not only ensures accuracy but also facilitates rapid iteration and production of complex geometries, making it indispensable in industries ranging from entertainment and gaming to industrial design and beyond.

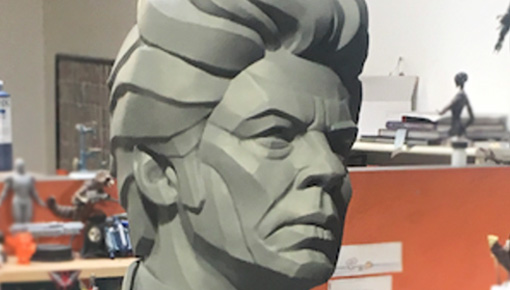

MJP

Multijet Printing

Gentle Giant Studios excels in MJP (MultiJet Printing) 3D printing, harnessing this technology to produce high-quality, detailed prints with exceptional speed and accuracy. MJP utilizes a precise inkjet printing process that deposits layers of photopolymer resin, which are then cured with UV light to solidify the model. This method allows Gentle Giant to create intricate prototypes and highly detailed collectibles that faithfully replicate original designs with fine features and smooth surfaces. The versatility of MJP enables rapid prototyping and production of end-use parts across various industries, showcasing Gentle Giant’s commitment to delivering superior quality and innovation in 3D printing solutions.

Color

3D Printing

DLP

Resin Printing

How DLP Printing Works

- A 3D model is sliced into thin, digital layers.

The build platform is lowered into a vat of liquid resin. - A digital light projector flashes the shape of the current layer onto the resin, curing it instantly.

- The platform rises slightly, a new layer of resin replaces the previous one, and the process repeats until the part is completed.

- Post-processing—such as rinsing, UV curing, and minor finishing—delivers a ready-to-use part.

Why Choose DLP 3D Printing?

If your project requires speed, precision, and exceptional detail, DLP is an ideal solution. From custom-fit medical devices to visually stunning prototypes and functional components, DLP delivers both quality and efficiency to meet today’s demanding production needs.

Discover how DLP 3D printing can elevate your next project at 3D Printing Los Angeles—where technology meets artistry.

Post Processing & Paint Services